UM4000 Hopper Wood Chipper

UM4000 Hopper Wood Chipper

The UM3600 wood chipper is able to efficiently handle large volumes of wood, branches, stumps and other plant waste.

- Mobility system:Tracked / Trailed / Fixed type

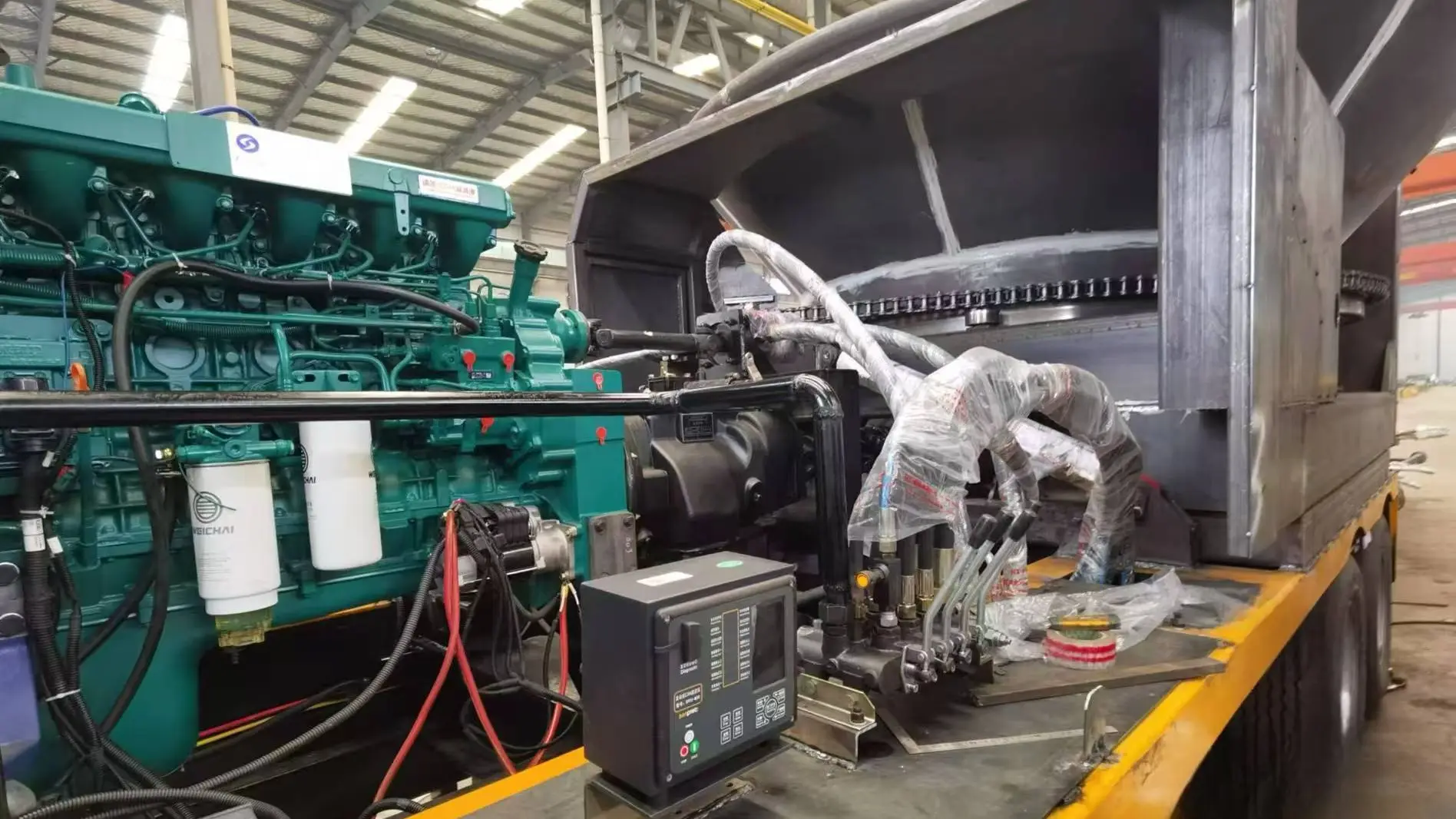

- Power supply type:Diesel / Electric type

- Engine make: Cummins / Weichai

Description

Unimax UM4000 бункерный измельчитель древесины – это высококлассная и высокопроизводительная дробилка, обладающая удивительной универсальностью. Она особенно хорошо подходит для выполнения различных партий работ по дроблению соломы или измельчению древесины. Одним из ее неоспоримых преимуществ является мобильность, позволяющая легко и гибко перемещать ее во время полевых работ, что значительно повышает удобство ее использования в различных рабочих условиях.

Эта надежная машина имеет привлекательный диаметр ванны 2,6 метра и проем 4 метра. Эти размеры не только способствуют его большой производительности, но и позволяют обрабатывать значительный объем материалов за один раз. Оснащенный мощным двигателем Weichai 530HP, Unimax UM4000 имеет прямой привод. Такая конструкция гарантирует, что машина сможет эффективно перерабатывать любое сырье из биомассы в обломки с высоким уровнем безопасности. Будь то прочные деревянные бревна или объемная солома, эта дробилка с легкостью их раздробит. Полученные обломки могут быть эффективно использованы в качестве энергии биомассы, играя решающую роль в обеспечении устойчивого развития энергетики и рециркуляции ресурсов в секторе энергетики биомассы.

| Model | UM3000 | UM3300 | UM3600 | UM4000 |

| Rotor diameter (mm) | 600 | 600 | 670 | 720 |

| Rotation speed (rpm) | 960 | 960 | 960 | 960 |

| Number of cutters (pcs.) | 10 | 10 | 10 | 10 |

| Engine power (hp) | 430 | 430 | 530 | 530 |

| Socket diameter (mm) | 3000 | 3300 | 3600 | 4000 |

| Maximum material diameter (mm) | 1600 | 1800 | 2350 | 2600 |

| Production capacity (tons per hour) | 10-20 | 20-30 | 25-40 | 35-45 |

| Socket depth (mm) | 1210 | 1210 | 1210 | 1210 |

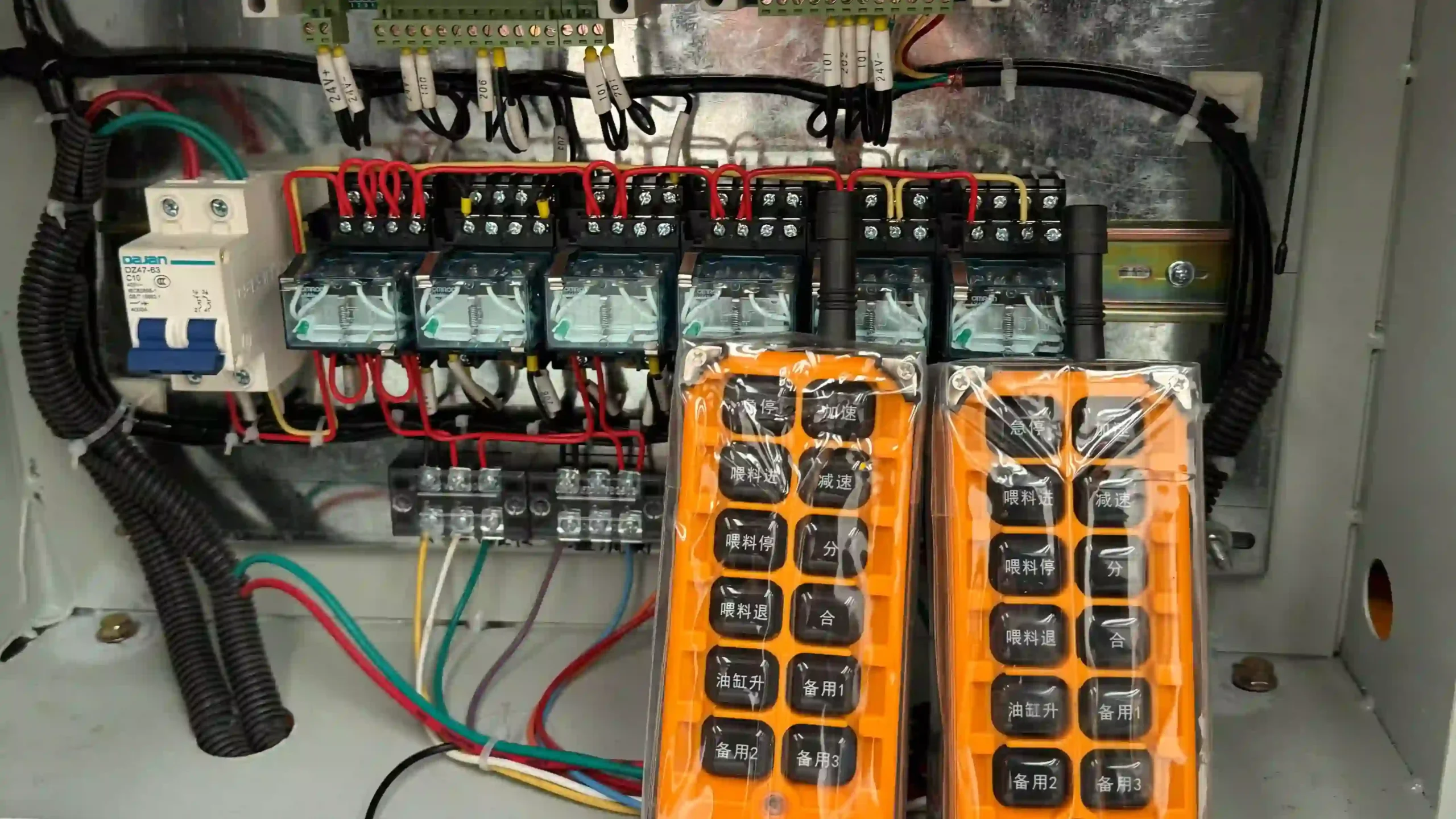

| Feeding control method | hydraulic remote control | hydraulic remote control | hydraulic remote control | hydraulic remote control |

| Weight (T) | 12 | 15 | 17 | 18 |

| Size L*W*H (mm) | 6000*3000*4000 | 6700*3300*4000 | 7500*3600*4200 | 7500*4000*4200 |

Characteristics

- Versatility

The unit can handle a variety of wood types including wood waste, tree roots, stumps, branches, building sheathing, boardwalks, cotton stalks, corn stalks, straw, stalks, etc.

- Durability and reliability

The abrasive roller is made of silicon manganese spring steel for exceptional wear resistance and durability. The knife retaining plate is made of manganese sheet steel, showing high resistance to deformation, impact and wear.

The crushing machine is made of quality materials, which ensures its durability and reliability in operation.

- Adjustable chip size

For example, a biomass power plant may need to burn straw, waste wood or branches. The boiler requires straw to be 6-10 cm long and wood and branches to be 5-8 cm or smaller. The output size is determined by the diameter of the sieve openings, which can be adjusted to suit the needs.

- High performance

The unit is equipped with a powerful engine that provides high performance and efficiency.This power allows you to process large volumes of wood in a short time, which is especially useful for large logging companies and wood processors.

- Dual control system

There are two ways of operation: by control panel and remote control. Automatic control of the complete set of mechanisms, including feeding system, unloading system, emergency stop, reversing system, etc. The effective control distance of the remote control is 80m. The automatic control system makes it convenient to operate and improve the safety of work.

Easy maintenance

The hydraulic lifting device can lift the intake system at a high angle when the machine needs service. The rotor will be open for easy operation. Reduced labor costs and no need for copper taps.

Intelligent reversing system

Automatic operation control. The hopper will rotate in the opposite direction if the load is too large, so there is no need to worry about the problem of material jamming.

- Optional power supply type and loading method

The loading methods are divided into tracked, traction, mounted, which can be selected according to the working conditions, and we offer electric motors and diesel engines as the power source.

Energy system

Diesel type

Electric type

Crushing system

Rotor with knives

Rotor with hammers

Mobility system

Track type

Trailer type

Fixed type

CHAVO on branch shredders

Hopper shredders are equipped with two types of working elements on the rotor - hammers and knives. Hammers are designed for crushing wood with nails, such as construction shuttering, while knives are more suitable for processing waste wood, roots, stumps, branches, shuttering, board scraps, cotton stalks, corn stalks, straw and other plant residues.

Both Unimax horizontal and hopper shredders efficiently process wood waste into marketable products. The choice between the two depends on the specific application: type of material to be processed, required size and fraction uniformity, mobility, available space and budget. Horizontal shredders allow for continuous loading of long, straight materials, while hopper models are ideal for processing bulky and shapeless materials such as whole trees, stumps, brushwood and construction waste.

Of course, tell us about your raw materials and applications and we will recommend the most cost-effective equipment. If the raw material is intended for recycling, our engineers can develop a production line solution for you.

We are a manufacturer with more than 20 years of experience. We have our own storage workshop, production workshop, assembly workshop, etc. We can provide comprehensive customization and after-sales support. No middlemen to earn differences, only lower prices and better support for you.

Two drive types are available - diesel and electric. We offer EPA/CE certified Cummins diesel engines. Customers can also choose economical and reliable engines from Chinese brands such as Weichai and other proven manufacturers.

Standard safety features include: emergency stop buttons, safety guards, remote controls, automatic shutdown systems and a hydraulic hopper tilt mechanism for easy maintenance. These solutions ensure operator protection and safe operation of the equipment.

Yes, as an agency, you will not only enjoy exclusive pricing, but also receive annual discounts. In addition, our marketing team will provide you with terminal customer resources in your area.

The following factors influence the longevity of shredders: the quality and durability of the materials used, regular maintenance, proper operation of the equipment (reducing wear and tear) and rational operation. With proper maintenance, the machine can last 15-20 years.

Leading manufacturer of wood chippers

We have a 70,000 square meter manufacturing facility with 500 skilled technicians with 23 years of manufacturing experience and achieve the highest production efficiency in the industry, with a lead time to delivery of only 20 days.

After laser cutting, the workpieces are successively subjected to precision machining. We operate more than 200 CNC machines in our facility, and critical parts are milled on gantry milling machines, which ensures higher strength compared to welded structures.

The cutting roller is connected to the torch shaft rotor by five radial stiffeners, which increase the stability of the structure. The cutting edges are sharpened on a CNC portal milling machine, after which the equipment is precisely balanced. This process ensures minimum vibration and maximum efficiency of each chipper roller.

Equipped with a remote control system. Komatsu's tracked platform allows the hopper shredders to be operated up to 50 meters away, with a maximum speed of 2000 m/h and the ability to traverse up to 30 degrees of elevation.

Cummins and Weichai diesel engines provide high performance for efficient shredding, with affordable after-sales service and parts supply worldwide for both engine brands.