| Model | WDL1080 | WDL1380 | WDL1690 |

| Rotor diameter (mm) | 800 | 800 | 1100 |

| Frequency (rpm) | 763 | 763 | 800 |

| Engine power (hp) | 430 | 480 | 550 |

| Receiving window size (mm) | 1300 | 1400 | 1600 |

| Capacity (tons per hour) | 15-25 | 20-30 | 30-40 |

| Weight (T) | 16 | 19 | 21 |

| Dimensions (L * W * H) (mm) | 11000*2900*3400 | 11000*3000*3400 | 11000*3000*3900 |

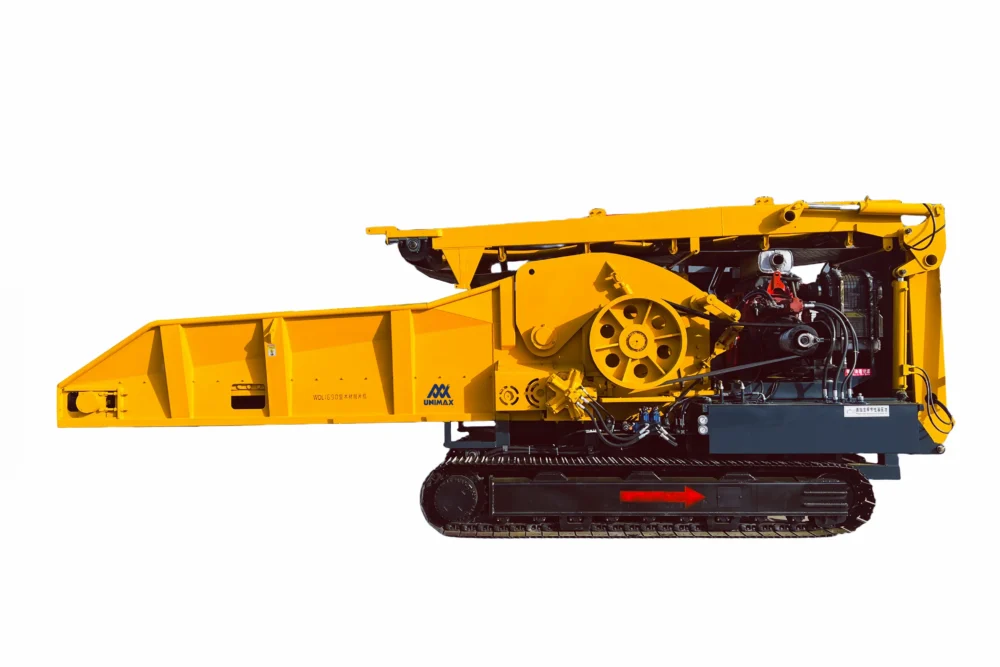

WDL1690 Horizontal Wood Chipper

WDL1690 Horizontal Wood Chipper

The WDL1690 horizontal shredder is ideal for processing wood raw materials (timber, branches, boards, lumber, wood core, building templates, roots, bark, veneer waste, chipboard, fiberboard) and non-wood raw materials (sugar cane, reeds, bamboo).

- Mobility system:Tracked / Trailed / Fixed type

- Power supply type:Diesel / Electric type

- Engine make: Cummins / Weichai

Description

The Unimax Series WD Horizontal Shredder is designed to efficiently process yard waste, brush and mixed wood into marketable products, making it an ideal choice for niche markets such as municipal recycling, pallet recycling, lot clearing, nurseries and tree care recycling. With large feed openings and low sidewalls, whole trees and other long materials are fed with fewer restrictions. Intelligent chain feeding system that can automatically adjust the feeding speed to avoid idling when the machine is fully loaded, making feeding smoother and greatly increasing productivity.

Characteristics

- Versatility

The unit can handle a variety of wood types including wood waste, tree roots, stumps, branches, building sheathing, boardwalks, cotton stalks, corn stalks, straw, stalks, etc.

- Durability and reliability

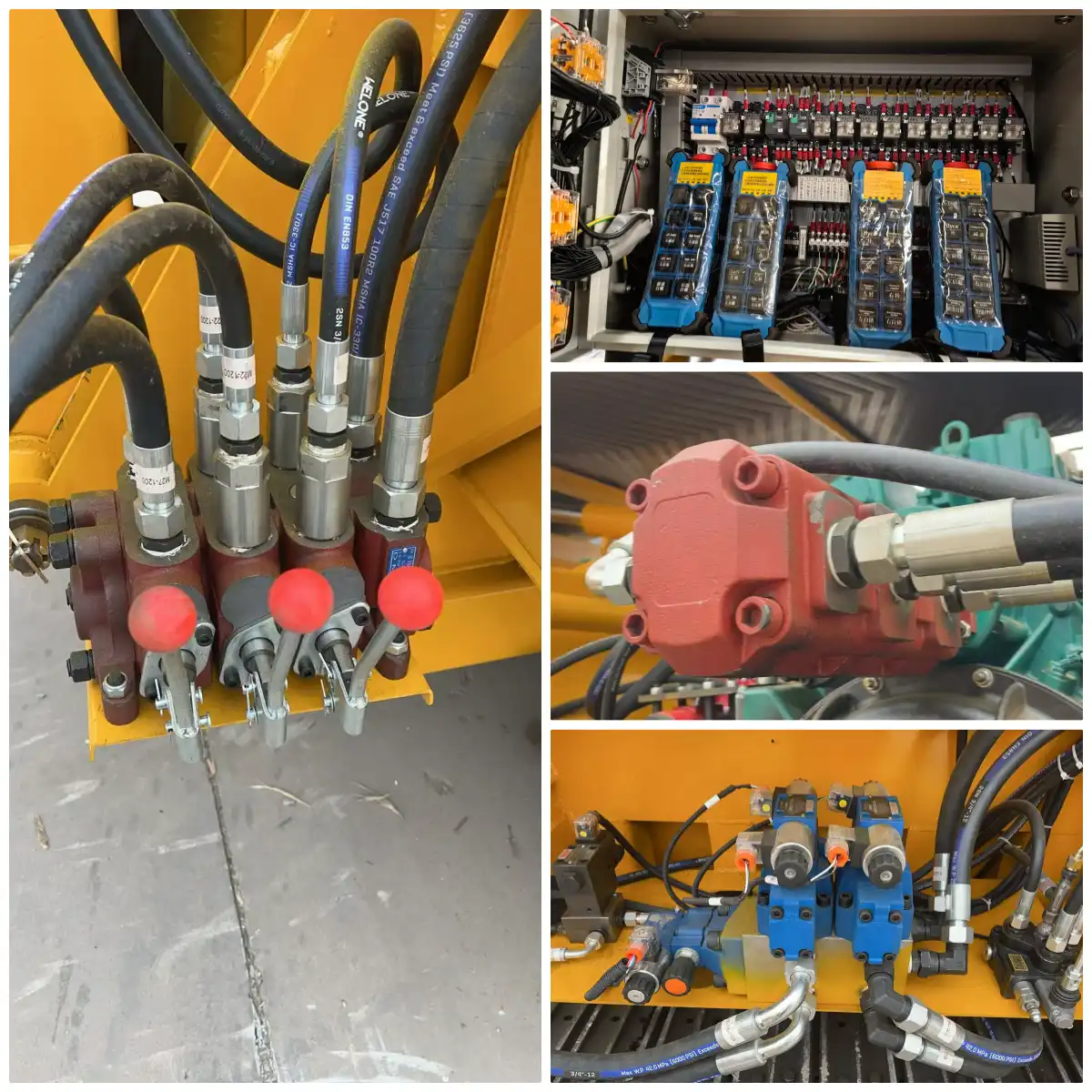

The blade rotor is made of silicon manganese spring steel for exceptional wear resistance and durability. The pressure blade plate utilizes sheet manganese steel that demonstrates high resistance to deformation, impact and wear. The pressure blade holder features a bushing system with nuts in the screw holes, providing convenient bushing replacement during maintenance when screws age. Reduces maintenance costs while providing powerful crushing force.

- Forced automatic feed system

Start the oil pump, the oil cylinder piston extends and retracts, the rotary device is raised or lowered, then the top feed roller automatically adapts to the nature of the raw material. This function allows the machine to adapt to a wide range of raw materials, and the feeding process becomes smoother. We have obtained a patent for it.

- Adjustable chip size

For example, a biomass power plant may need to burn straw, waste wood or branches. The boiler requires straw to be 6-10 cm long and wood and branches to be 5-8 cm or smaller. The output size is determined by the diameter of the sieve openings, which can be adjusted to suit the needs.

- Easy maintenance

Thanks to the hydraulic system, it is easy and simple to open the machine cover to check or replace the cutter, mesh, etc. For shredding wood waste and pallets with nails it is enough to replace the blades and hammers.

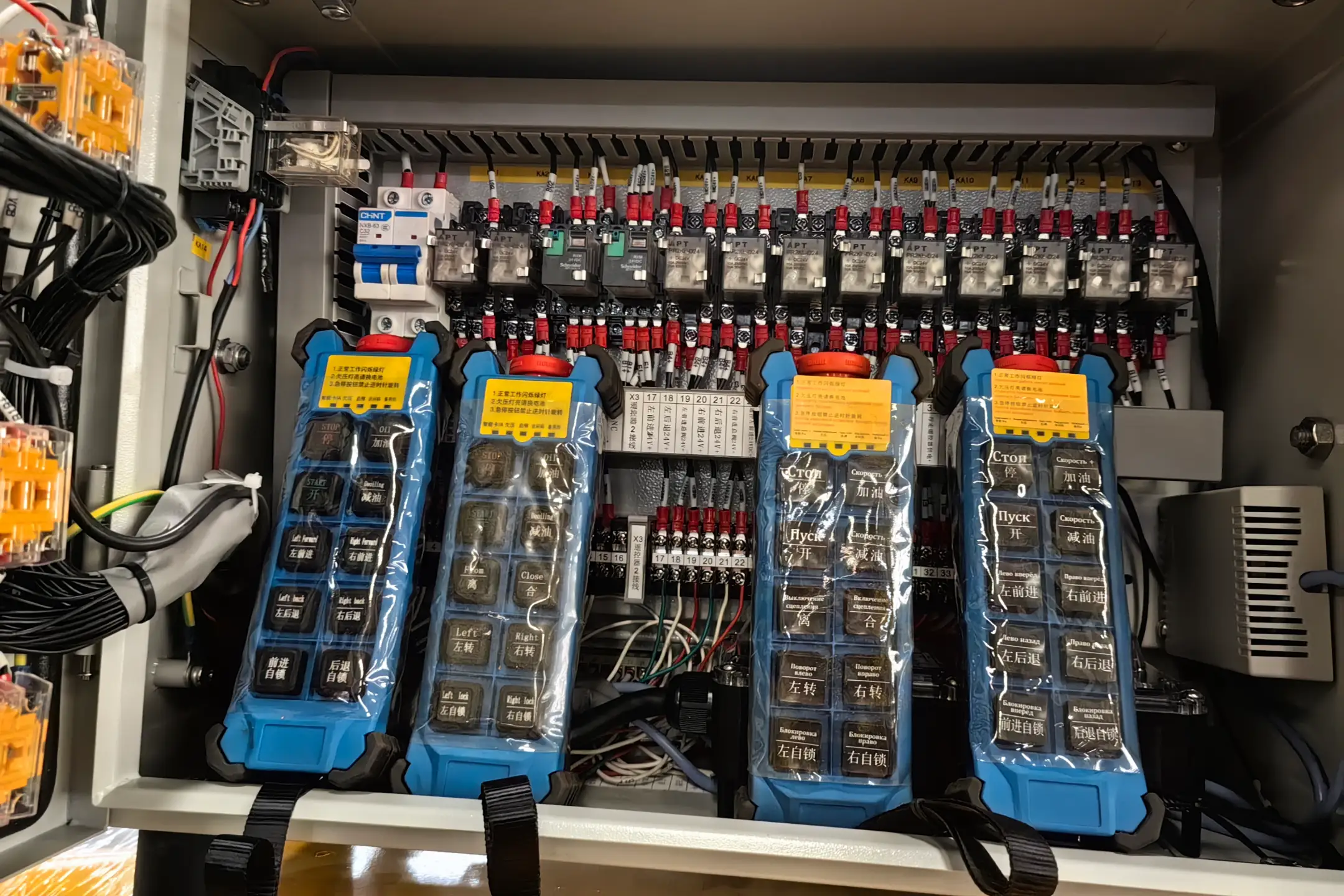

- Dual control system

The system has two modes of operation - fixed electric control cabinet and remote control interface, which together improve the safety of operation and provide convenience to the user.

Locking the control of the feed system

During normal operation, the feed roller and conveyor run simultaneously. As soon as a blockage occurs, the feed system will stop feeding to protect the machine from blockage.

The pulley is secured by a locking device with an internal hole.

Easy to assemble and disassemble. No traditional brutal assembly and disassembly. Protects the main motor. It facilitates maintenance and extends the life of the main motor.

- Optional power supply type and loading method

The loading methods are divided into tracked, traction, mounted, which can be selected according to the working conditions, and we offer electric motors and diesel engines as the power source.

Energy system

Diesel type

Electric type

Crushing system

Rotor with knives

Rotor with hammers

Mobility system

Track type

Trailer type

Fixed type

CHAVO for horizontal wood chippers

Horizontal wood chippers ? Unimax Horizontal wood shredders allow continuous feeding of long and straight materials such as lumber, branches, hump wood, laths, logs, roots, bark, veneer waste, chipboard, fiberboard, sugar cane, reeds, bamboo and others.

Both Unimax horizontal and hopper shredders efficiently process wood waste into marketable products. The choice between the two depends on the specific application: type of material to be processed, required size and fraction uniformity, mobility, available space and budget. Horizontal shredders allow for continuous loading of long, straight materials, while hopper models are ideal for processing bulky and shapeless materials such as whole trees, stumps, brushwood and construction waste.

Of course, tell us about your raw materials and applications and we will recommend the most cost-effective equipment. If the raw material is intended for recycling, our engineers can develop a production line solution for you.

We are a manufacturer with more than 20 years of experience. We have our own storage workshop, production workshop, assembly workshop, etc. We can provide comprehensive customization and after-sales support. No middlemen to earn differences, only lower prices and better support for you.

Two drive types are available - diesel and electric. We offer EPA/CE certified Cummins diesel engines. Customers can also choose economical and reliable engines from Chinese brands such as Weichai and other proven manufacturers.

When the machine is overloaded and blocked, the metal chain conveyor, pressure roller and rotor with blades will simultaneously rotate in the opposite direction to unload the blocked material, effectively reducing equipment damage.

Yes, as an agency, you will not only enjoy exclusive pricing, but also receive annual discounts. In addition, our marketing team will provide you with terminal customer resources in your area.

The following factors influence the longevity of shredders: the quality and durability of the materials used, regular maintenance, proper operation of the equipment (reducing wear and tear) and rational operation. With proper maintenance, the machine can last 15-20 years.

Leading manufacturer of wood chippers

We have a 70,000 square meter manufacturing facility with 500 skilled technicians with 23 years of manufacturing experience and achieve the highest production efficiency in the industry, with a lead time to delivery of only 20 days.

After laser cutting, the workpieces are successively subjected to precision machining. We operate more than 200 CNC machines in our facility, and critical parts are milled on gantry milling machines, which ensures higher strength compared to welded structures.

The cutting roller is connected to the torch shaft rotor by five radial stiffeners, which increase the stability of the structure. The cutting edges are sharpened on a CNC portal milling machine, after which the equipment is precisely balanced. This process ensures minimum vibration and maximum efficiency of each chipper roller.

Equipped with a remote control system. Komatsu's tracked platform allows the hopper shredders to be operated up to 50 meters away, with a maximum speed of 2000 m/h and the ability to traverse up to 30 degrees of elevation.

Cummins and Weichai diesel engines provide high performance for efficient shredding, with affordable after-sales service and parts supply worldwide for both engine brands.