rich experience

- As a factory that has been engaged in the production of wood grinding machines for 23 years, we have a production base of 120,000 square meters and a staff of 500 employees. We are equipped with a variety of professional finishing equipment, which enables us to achieve high precision machining in the product manufacturing process. This ensures that the parts of our wood sanding machines are machined with a fineness that reaches the highest level in the industry, thereby increasing the overall productivity and quality reliability of our products. With our long-standing presence in the industry, we have in-depth technical knowledge and extensive manufacturing experience. This allows us to respond quickly to market demands, address various technical challenges and consistently present high quality wood chipper products that meet the diverse needs of our customers and take a leading position in the market.

Innovations

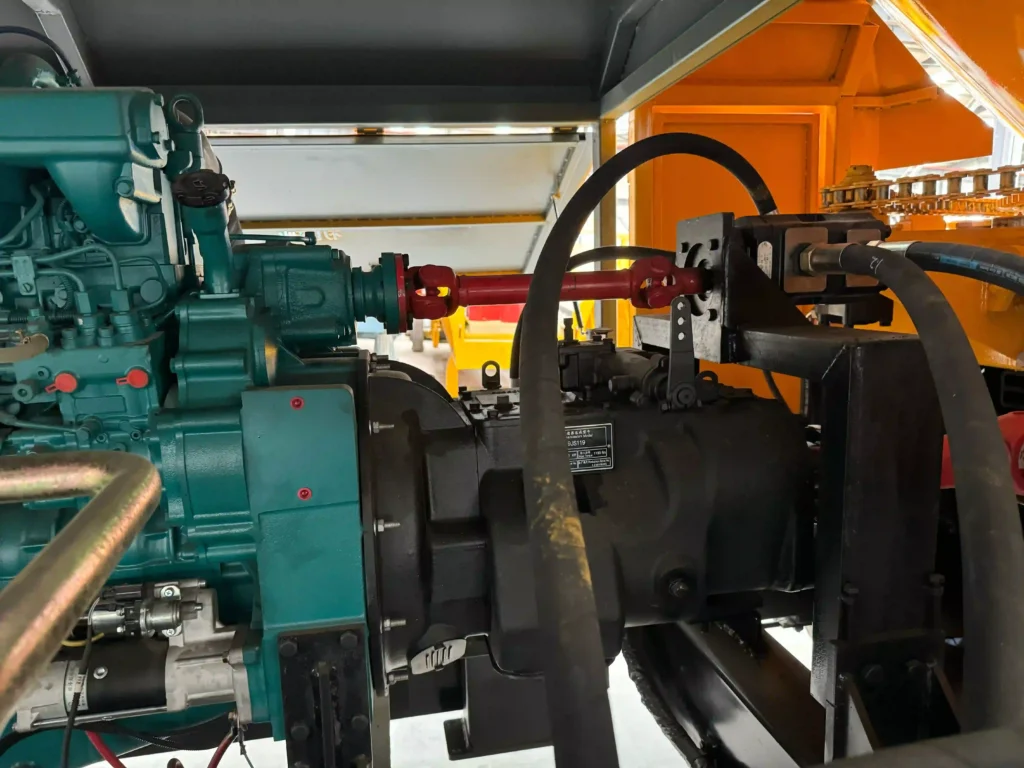

- We have applied an innovative design combining a tracked chassis and a wood grinder, allowing the originally stationary wood grinder to move freely and be able to traverse off-road terrain. For outdoor applications, our fully hydraulic wood grinder is equipped with diesel-powered hydraulic motors. Controlled through hydraulic control valves for the feeding and discharging systems, it provides a quick response to the operation, the 30% is more economical than traditional chippers while maintaining excellent safety. The whole machine is free of high voltage electricity and electric motors, providing reliable quality and exceptional performance. It is the optimal choice for outdoor wood crushing.

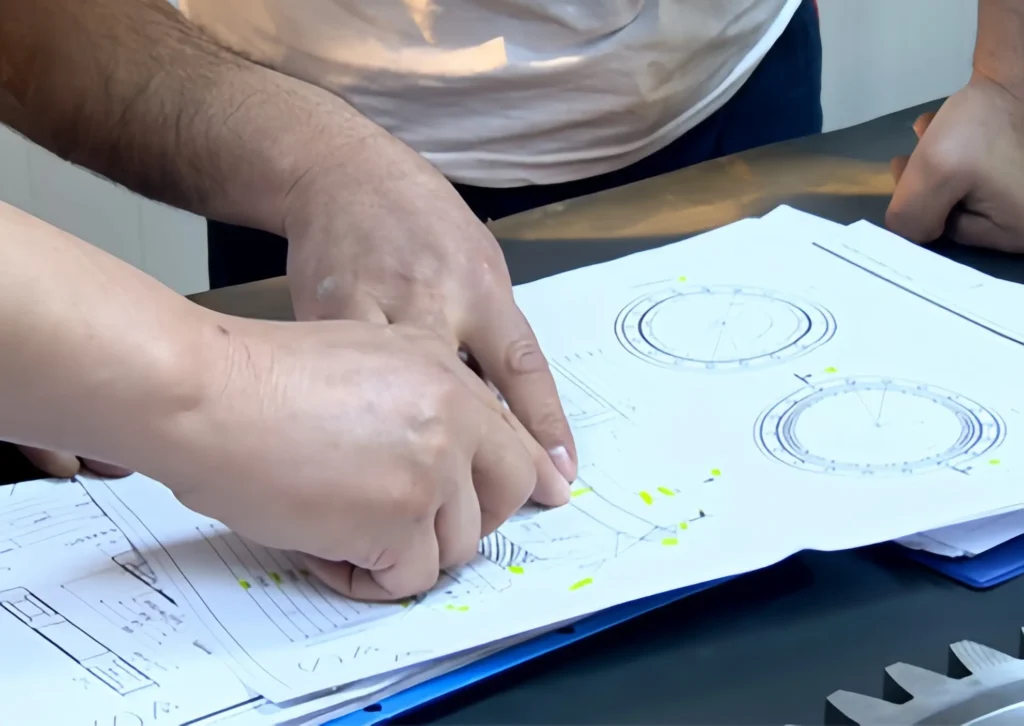

Design and research

- Requirements analysis

Based on market research and customer needs, clarify the performance requirements of wood crushers, such as type of material to be crushed, capacity requirements and applicable working conditions.

- Scheme development

Professional engineers design the overall structure of the product, including hydraulic system, feeding and unloading system, feeding system, chassis system.

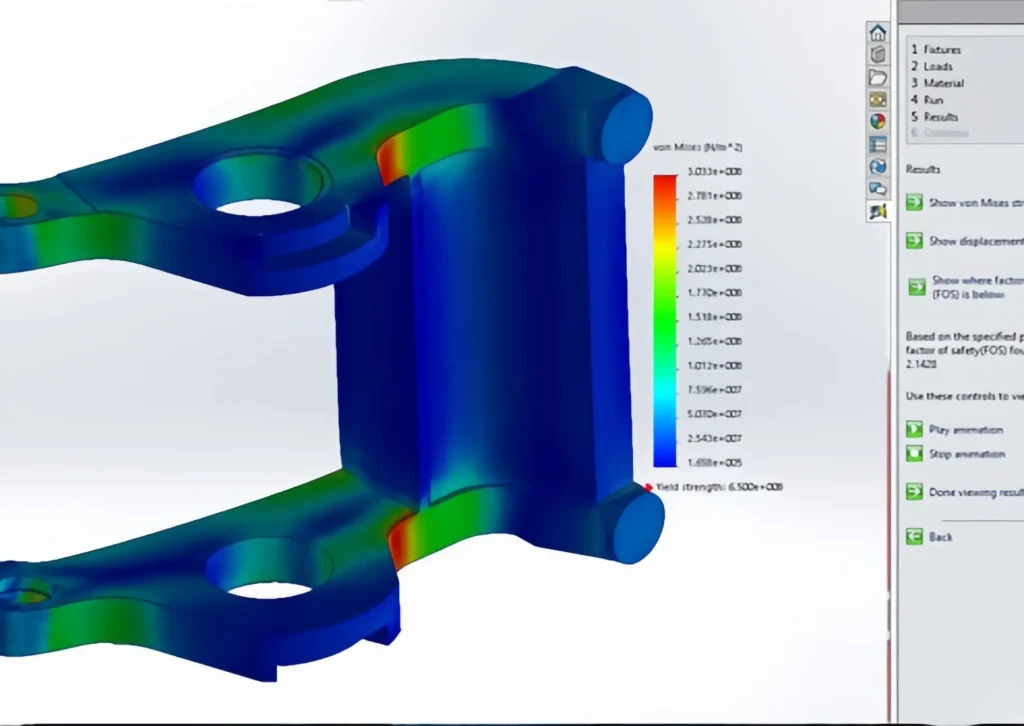

- Modeling and verification

Use software such as computer-aided design (CAD) and finite element analysis (FEA) to model and analyze the design scheme and optimize the structural design.

Purchase and inspection of raw materials

- Purchase of raw materials

Procurement of high quality raw materials such as steel, castings, hydraulic components, diesel engines and electrical components as per the project requirements.

- Quality assurance

Conducting stringent quality checks on procured raw materials, including chemical composition analysis, mechanical properties testing, dimensional accuracy measurement, etc.

Processing and production of components

- Processing

Use of CNC lathes, milling machines, drilling machines and other equipment to perform machining of metal parts by cutting to ensure dimensional accuracy and surface quality.

- Heat treatment

Performing heat treatment processes such as quenching and tempering on key components to improve hardness, strength and wear resistance of parts.

- Surface treatment

Perform surface treatments such as electroplating and spraying on parts to improve the corrosion resistance and appearance of the parts.

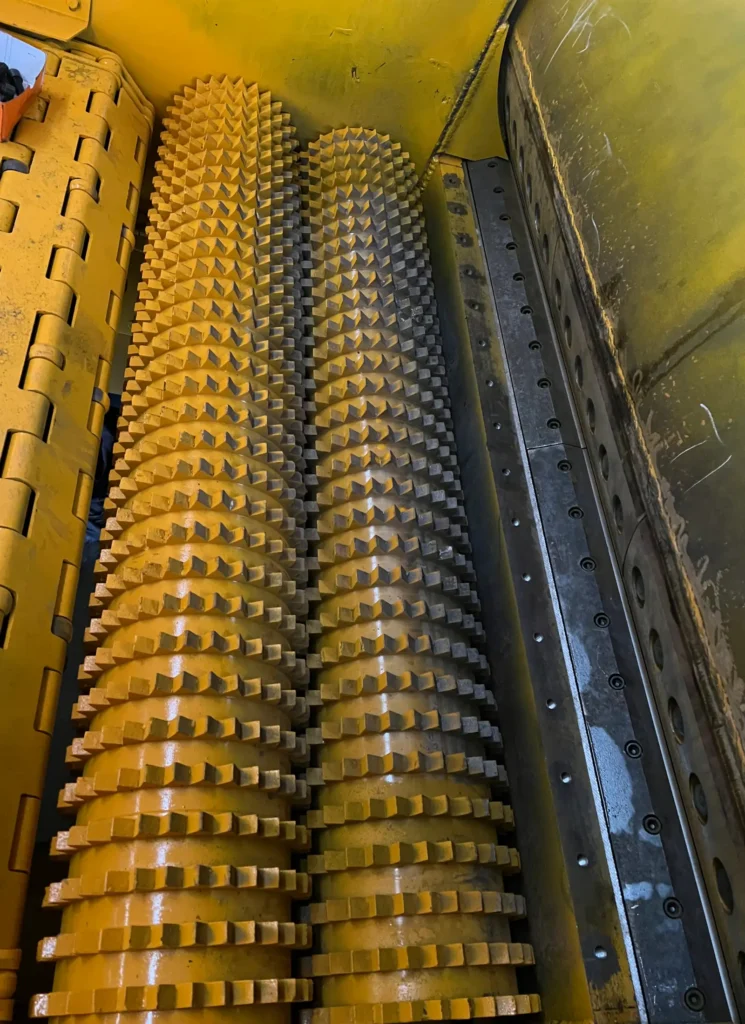

Installation and commissioning

- Component assembly

Assemble the machined components according to the assembly drawing to form the various components of wood chippers such as hydraulic power unit, diesel engine, blasde roller, etc.

- Final assembly and commissioning

Assemble all components as a whole, connect hydraulic lines, electrical circuits, etc., and then carry out commissioning.

Quality control and testing

- Appearance inspection

Assemble the machined components according to the assembly drawing to form the various components of wood chippers such as hydraulic power unit, diesel engine, blasde roller, etc.

- Performance testing

Conduct comprehensive operational tests on wood sander, including checking engine operating condition, cutting system operating condition, hydraulic system pressure, etc.

- Reliability test

Conduct reliability tests on wood grinders and simulate real-world operating conditions for long-term operation tests.